With rising trade demands, retrofitting legacy ports and developing smart hubs must go hand in hand to expand capacity, reduce emissions, and strengthen supply chains

International shipping produces about 3 per cent of global greenhouse gas emissions, and this share could grow as trade expands. While vessel efficiency is often the subject of discussion, ports – which handle more than 80 per cent of global trade by volume – are also central to making maritime logistics more energy efficient. They face mounting pressure to cut emissions while boosting throughput and resilience amid frequent supply-chain disruptions.

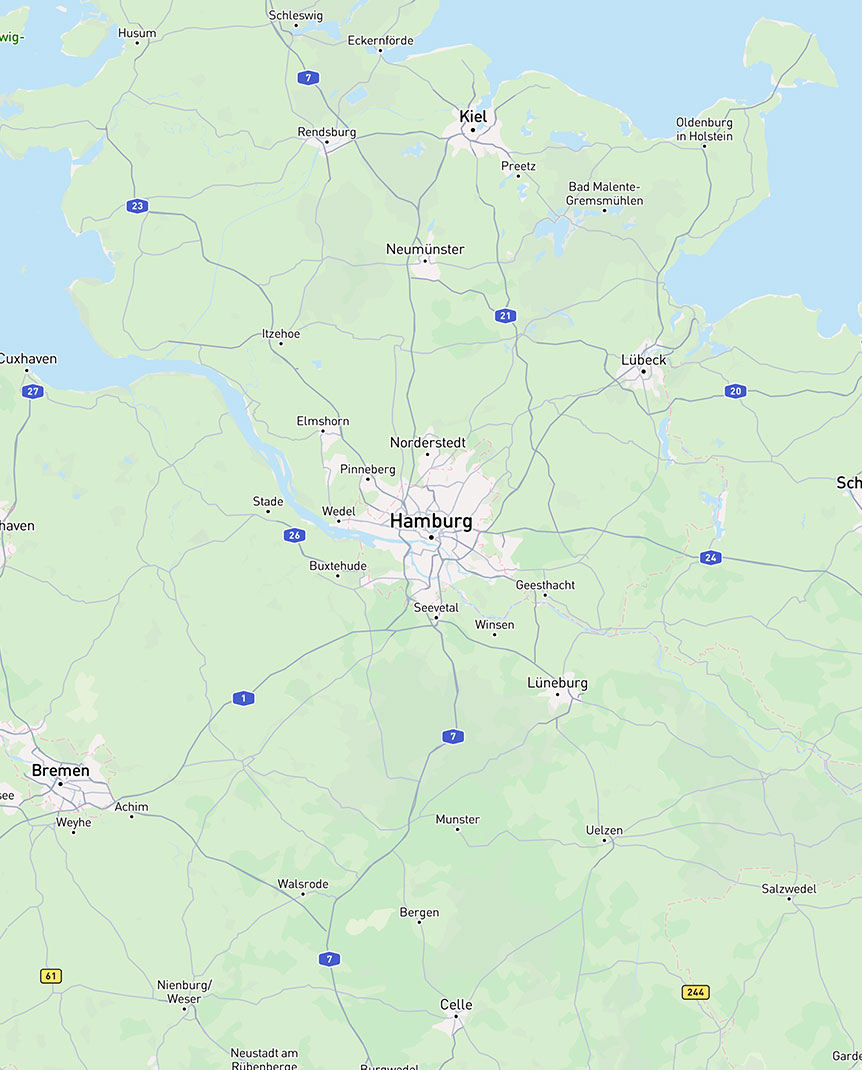

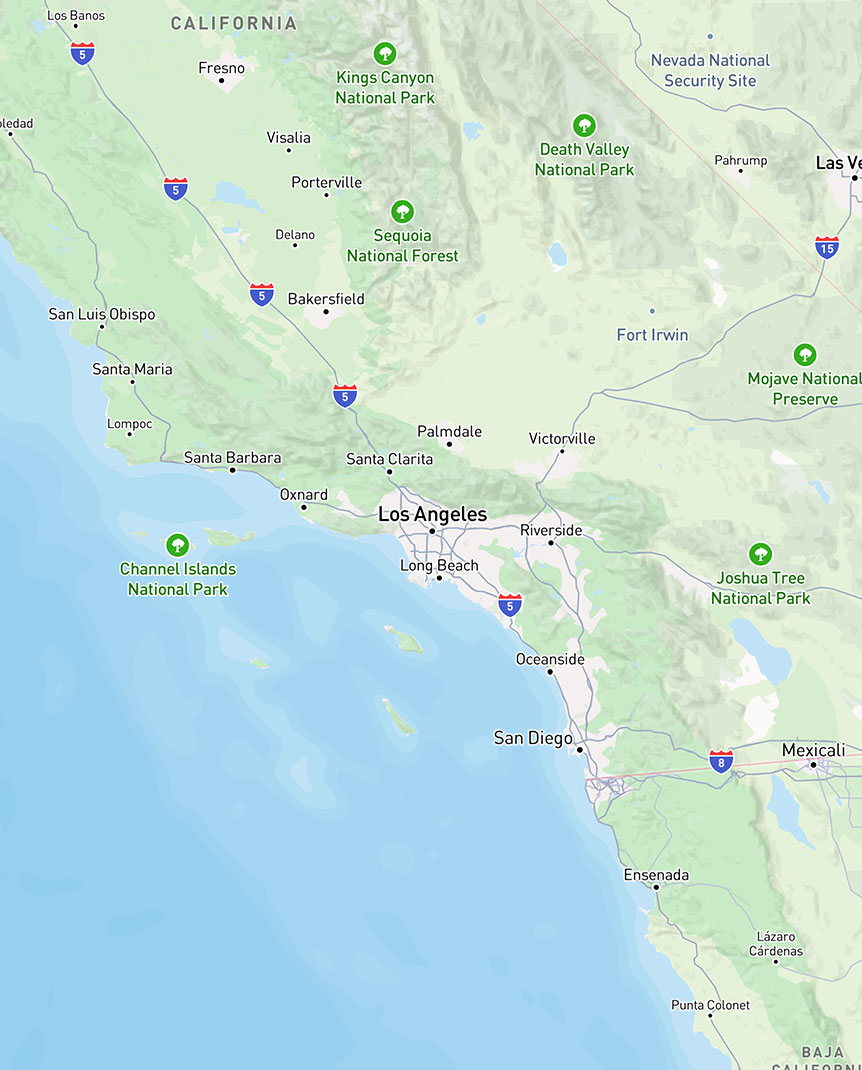

From Hamburg to Los Angeles, legacy ports are racing to upgrade their often ageing infrastructure. Meanwhile, a new wave of greenfield “smart ports” is emerging, designed around automation, renewable energy and seamless digital integration. By combining digital optimisation, reduced-emission equipment and resource-efficient design, these ports demonstrate a commitment to improving both operational and environmental performance.

Hamburg

Port of Neom

Los Angeles

Maintaining legacies for the future

Legacy hubs such as Hamburg, Rotterdam and Los Angeles typically pursue incremental upgrades. For example, “cold ironing” – the practice of supplying docked vessels with electricity from shore-based power sources – allows ships to turn off their engines while at berth. This has been implemented over the past two decades on the US West Coast, with Europe following suit.

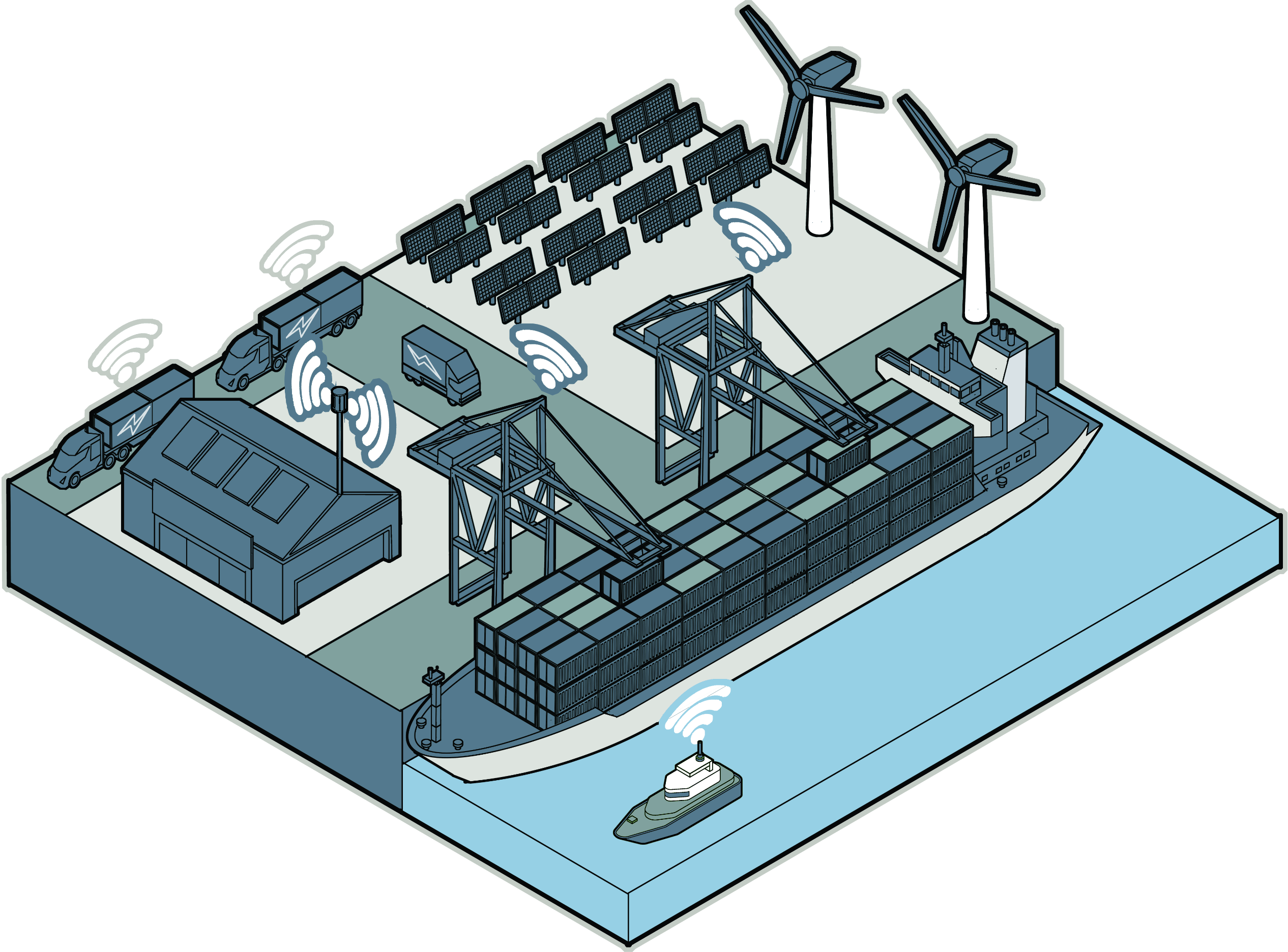

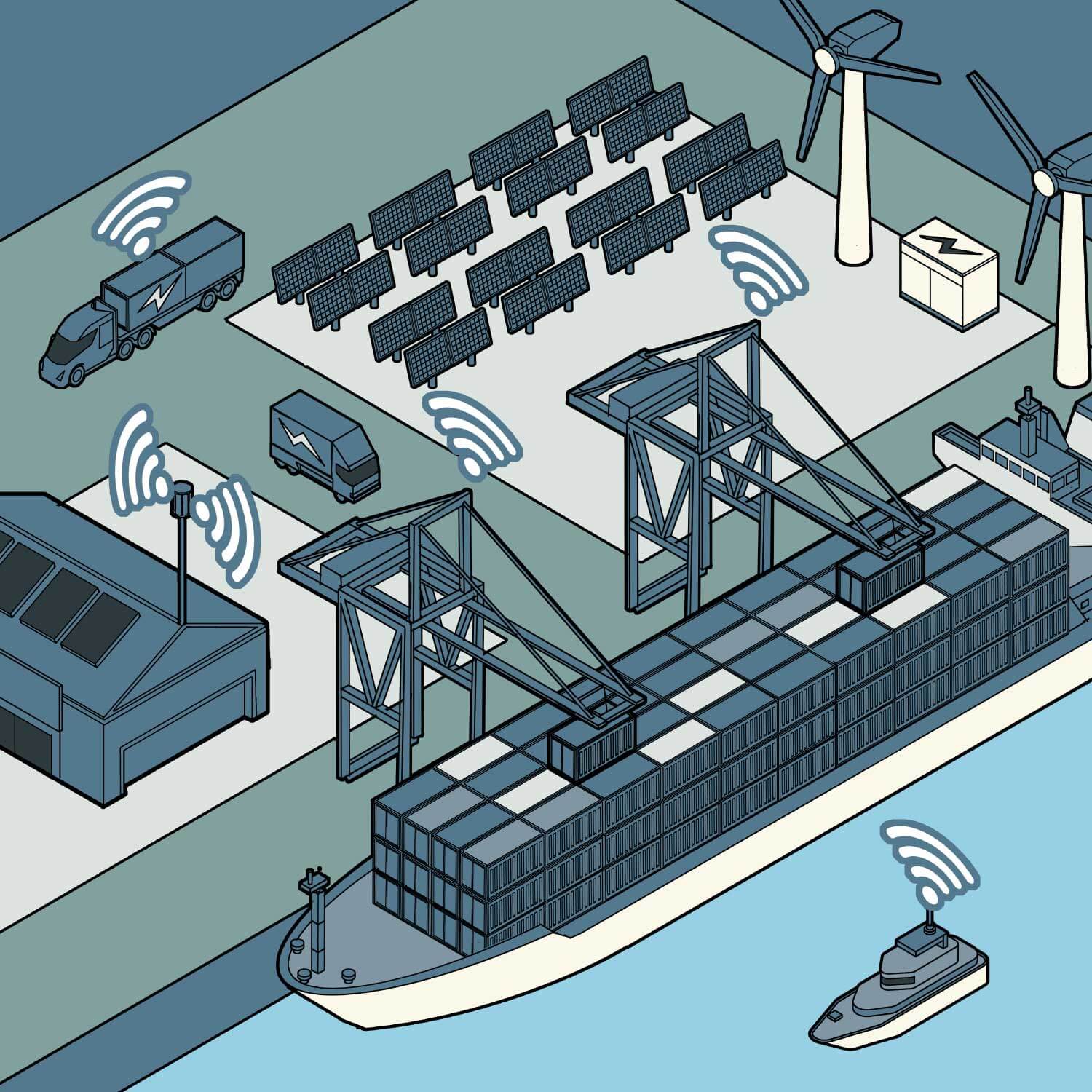

Retrofits are complicated by old infrastructure, patchy grid reliability and the need to minimise downtime. By contrast, smart ports – such as Port of NEOM, the fully automated logistics hub being developed within Oxagon, NEOM’s advanced industrial district in construction on the Red Sea, and Singapore’s Tuas Port – are being built from scratch with digital “full stack” systems, ensuring every operational, logistical and administrative layer is integrated into a single technology platform from the outset.

Melissa Blake, Operations Director at Port of NEOM, explains: “Older ports lack the electrical and communications backbone to support state-of-the-art systems. Starting from scratch will make this feasible and economically efficient, enabling us to scale with precision, embed resilience into every layer and converge automation, energy and data to redefine how a port operates.”

“Starting from scratch will enable us to scale with precision, embed resilience into every layer, and converge automation, energy and data, redefining how a port operates”

Melissa Blake, Operations Director at Port of NEOM

Cranes in place within Port of NEOM

As supply-chain expert Wolfgang Lehmacher notes, sustainable ports are evolving into more than just trade access points. “The aim is for them to become energy and data hubs,” he says. “Ports could even feed clean electricity into surrounding grids, extending their value beyond trade to community resilience.” Automation, AI-driven analytics, predictive maintenance and renewable-powered microgrids are not add-ons but fundamental design features.

Given that established hubs are responsible for the bulk of global container traffic, these solutions make the upgrading of legacy ports crucial – yet challenging. Retrofitting older ports is often costly, as many were not built for high-voltage shore power or renewable energy storage. Equally, the shift to partial automation demands investment in workforce reskilling and transitional support.

“The aim is for them to become energy and data hubs. Ports could even feed clean electricity into surrounding grids”

Wolfgang Lehmacher, supply-chain expert

Nevertheless, retrofits remain vital: knowledge-sharing between major hubs has accelerated the uptake of electrification, sophisticated monitoring through interconnected digital sensors and AI-assisted scheduling to optimise cargo handling. The result is a patchwork of improvements that, although uneven, still represents meaningful progress.

While many legacy ports rely on reskilling models to train existing employees to work with new systems, greenfield hubs are designing operations around a digitally fluent, high-tech workforce from the outset. For example, production specialists at NEOM are trained to oversee autonomous systems, run live configuration testing and troubleshoot AI-driven workflows. “These aren’t traditional crane operators – they’re systems integrators, data analysts and automation strategists. Their role is not to adapt to technology, but to shape it,” says Blake.

Building from the ground up

Adding to its existing operations with a new container terminal that is planned to commence phased opening from 2026, with full end-to-end automation by 2028, Port of NEOM is hoped to surpass the limitations of legacy sites. It will connect east–west trade lanes, with its location adjacent to one of the world’s busiest maritime corridors near the Suez Canal.

Construction under way includes a 900m quay and an 18.5m-deep channel for the world’s largest container vessels. Fully automated cranes are set to be operational by 2026, with autonomous vehicles and integrated warehousing to follow.

Digital renderings of Oxagon and Port of NEOM

Energy independence is a central focus of the port’s strategy. Its design incorporates significant on-site renewable generation, including solar installations, to support shore-power operations with cleaner and more resilient energy. While the port aims to maximise its use of renewable sources, there are also plans for complementary systems to ensure reliability and scalability as demand grows. “We’re building an all-electric container terminal,” says Blake.

“Cranes and vehicles will be electric, powered by solar panels and battery storage, along with energy from cranes as they lower containers, which will be fed back into the electrical system, creating a circular energy economy.” The AI-optimised energy management system will ensure that power is delivered only when needed. Port of NEOM is also using recycled steel for its quay walls.

“We're building an all-electric port where equipment and vehicles run on power from solar panels, battery storage and recovered energy fed back into the system, creating a circular energy economy”

Melissa Blake, Operations Director at Port of NEOM

Singapore’s Tuas Port will also embody a similar philosophy. Planned to consolidate the city state’s container operations into one mega-terminal, it will integrate AI-based planning to optimise logistics and a digital twin for real-time monitoring and analysis of operations. Tuas also has a long-term ambition for net zero emissions by 2050 using electric vessels and carbon-neutral alternatives, such as B100 biofuels. Both projects aim not only to boost efficiency, but also to redefine ports as platforms for innovation and sustainability.

Shore-to-ship power demonstrates the value of the smart hub. In North America and Europe, adoption has been strong but uneven, with many ports still experiencing a lack of reliable supply. In regions with weaker electricity distribution networks, rollout remains slow.

Melissa Blake, Operations Director, Port of NEOM

Automation follows a similar trajectory, with legacy ports introducing remote-controlled cranes and semi-autonomous yard vehicles. In 2026, Port of NEOM plans to deliver Terminal 1, featuring fully automated ship-to-shore (STS) cranes capable of handling the world’s largest container vessels, supported by electric gantry cranes designed to efficiently move and stack containers.

By 2028, delivery offerings are expected to include emissions tracking and AI-driven logistics that extend beyond the terminal. “We are building the infrastructure to integrate battery systems as they become more economical,” Blake explains. “Planned deployment will strengthen resilience against power outages, improve power quality, and enable self-generation both day and night as we scale.”

Crane arrival at Port of NEOM

Legacy and smart ports complement each other

Retrofitted legacy hubs and new smart ports may be seen to be in competition, but both are essential. Established gateways, such as Rotterdam and Los Angeles, will remain vital for trade. Incremental upgrades can keep them efficient while reducing their environmental impact.

Ports have become intelligent engines of global commerce, with retrofitted legacy hubs and greenfield smart ports reshaping the logistics landscape as complementary drivers. While legacy ports reveal the constraints of the past, smart ports show what’s possible when starting from scratch, with automation, renewables and digital integration incorporated from day one.

The Port of NEOM

Ultimately, says Lehmacher: “Sustainability is not just about meeting climate rules or 2050 goals; it’s about making ports dependable, efficient and ready for the future. The more predictable a port becomes, the more sustainable global trade will be.” Reducing greenhouse gas emissions from shipping and port operations – through means such as cleaner fuels and improved energy efficiency – is a significant challenge. Stakeholders demand net zero pathways, but core infrastructure varies widely in its readiness.

Legacy retrofits show the realities of constraints; smart hubs reveal the potential of fresh starts. “Together, these approaches demonstrate how ports are evolving to enhance resilience, expand capacity, meet climate change targets and streamline the efficiency of international commerce,” says Blake. “As global trade demands faster, cleaner and more resilient supply chains, the ports that embrace this shift will define the next era of connectivity.”